Wire Ampacity & Gauge Charts: Your Guide To Electrical Safety

Ever wondered what keeps the lights on and the devices humming, all while keeping you safe? It all boils down to understanding wire ampacity, the unsung hero of electrical systems.

Ampacity, in its essence, is the maximum current a wire can handle without overheating, a critical safety factor that prevents fires and ensures the longevity of your electrical circuits. This seemingly simple concept is the cornerstone of any electrical project, from the smallest home repair to the largest industrial installation. Ignoring it can lead to dangerous consequences, making a clear understanding of wire ampacity essential for anyone working with electricity.

Navigating the world of electrical wiring can feel like deciphering a secret code, but understanding the key terms unlocks the door to safe and efficient electrical work. The American Wire Gauge (AWG) system, for example, is a standard for wire sizes, with each gauge representing a specific wire diameter and, consequently, a specific ampacity. A deeper dive into these concepts can make a world of difference.

Let's break down some key aspects of wire ampacity and related concepts. The AWG (American Wire Gauge) system provides a standardized way to measure wire sizes, essential for electrical applications. Understanding AWG involves knowing that the gauge number and wire diameter have an inverse relationship; a smaller gauge number indicates a larger wire diameter. For example, a 14 AWG wire is smaller than a 10 AWG wire. The AWG system is fundamental, and a wire size chart with detailed specifications on wire diameter, resistance, and ampacity is crucial for selecting the appropriate wire size for a given application. Furthermore, circular mils are another unit of measurement used, particularly when assessing the cross-sectional area of a wire, which is directly related to its current-carrying capacity. The AWG system is obtained from drawing many operations to make the required gauge of wire.

The importance of selecting the right wire size cannot be overstated. Ampacity is the maximum current that a conductor can carry continuously under the conditions of use without exceeding its temperature rating. Consider this: choosing a wire with an ampacity rating that is too low for the intended current load is a recipe for disaster. The wire will overheat, potentially damaging insulation, causing short circuits, and even igniting a fire. Conversely, selecting a wire with an ampacity rating that is far greater than what's needed is generally safe, but it can be a costly over-engineering. Therefore, the goal is to select a wire that is rated precisely for the expected load, ensuring safety, efficiency, and cost-effectiveness.

The question of "how many amps can the 00 gauge wire handle?" is one that often arises in electrical planning, especially for larger circuits. A 00 (also written as 2/0) gauge wire at 75C can typically handle around 175 amps, making it suitable for a variety of high-power applications. However, it is important to note that this is a general figure, and the exact ampacity can vary slightly based on the insulation type, ambient temperature, and installation method. Also, the 00 AWG wire is often custom used as a 150 amp wire size, as its ampacity is slightly less than what the 1/0 gauge wire (rated for 150 amps) can handle at the same temperature.

Choosing the right wire size involves several considerations beyond just the ampacity. The ambient temperature, the type of insulation, and the installation method can all affect a wire's ability to dissipate heat and carry current safely. For instance, wires bundled together in a conduit will not dissipate heat as effectively as wires run in open air. This is why derating factors are often applied to ampacity ratings to account for these conditions. For instance, a 2 AWG gauge aluminum wire has an ampacity of 90A at a median 75C (167F) temperature.

For instance, a 2/0 copper wire can carry up to 200 amps, whereas a 2 AWG copper wire can carry 125 amps. A 2/0 aluminum wire carries 150 amps at 90 degrees Celsius. Therefore, 2 metal wires are ideal for your 100 amp sub panel to prevent issues like short circuits that might result in electrical harm to your components.

The unit of current is Amperes, often shortened to "amps". The use of accurate wire size for circuits is important to avoid damage, overheating, and fire hazards. It is measured in amperes (amps). It is crucial to understand that ampacity is the maximum continuous current carrying capacity of a wire inside a cable or raceway. When designing electrical systems, engineers and electricians use wire ampacity charts to find the accurate wire size for projects based on wire gauge, insulation type, and temperature ratings.

The amperage rating of a cord is a function of the wire gauge, the number of current-carrying conductors, and the length of the cord. The wire ampacity calculator will quickly calculate the maximum allowable current through a conductor based on wire size (AWG or kcmil), wire insulation, and conductor material. The selection of wire gauge and ampacity is essential to comply with electrical codes and ensure the safety and efficiency of your circuits.

Lets get started with wire ampacity charts and wire gauge charts. Check the wire gauge and look at the amp rating of the wire at its maximum. This means understanding wire amp ratings and how amps are defined, with a useful ampacity chart. It's also essential to consult the National Electrical Code (NEC) for detailed guidelines and safety regulations.

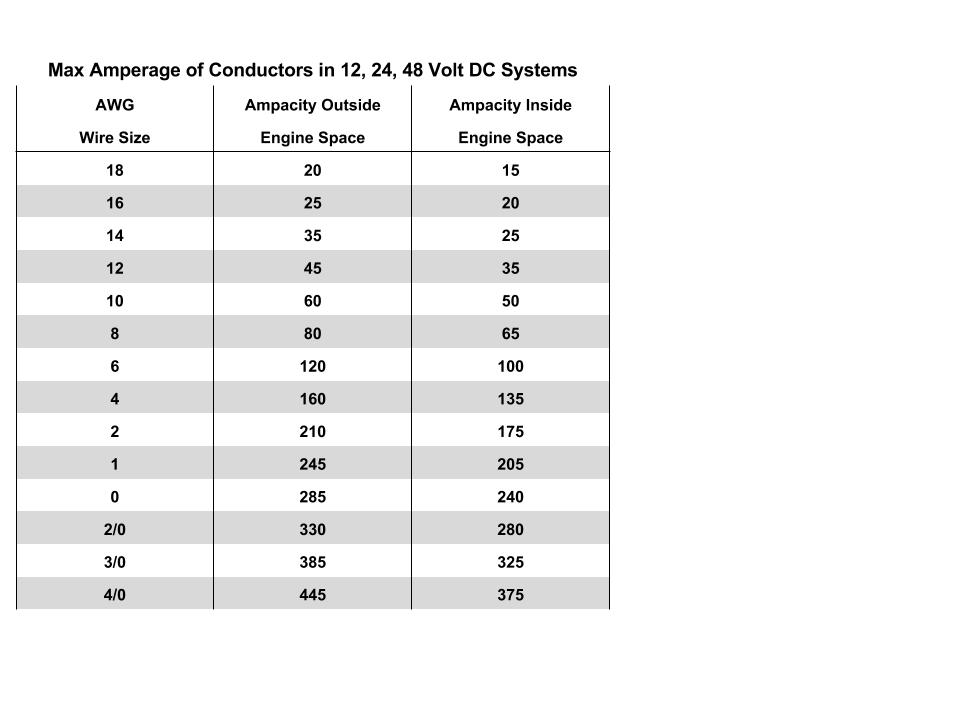

For example, 3/0 AWG copper has an ampacity of 200 amps at 75C, while 3/0 AWG aluminum has an ampacity of 155 amps at 75C. 1/0 or 0 AWG copper wire carries 125A while aluminum wire carries 100A. 2/0 is a rare wire size, but engineers use it all the time. Based on the 2017 NEC, careful consideration of these factors is important for a safe and reliable electrical installation. Automotive wire amperage capacity charts provide recommended lengths and amperages while maintaining a 2% or less voltage drop at 12 volts.

To work with electrical systems safely, knowing how many watts a wire can handle is crucial. This is quite easy to calculate. In addition to the wire ampacity, voltage also plays a role in determining the power (watts) a wire can handle. The power (watts) can be found by multiplying the voltage by the current (amperes) running through a circuit. The wire gauge wattage charts provide a useful guide for AWG wires (4/0 AWG to 14 AWG) for 15 amp service + 15 amp breaker wire size. Engineers use it all the time.

As the gauge number decreases, the wire size increases, ranging from 40 gauge down to 0 gauge or 0.325 inches. Working with wire of a lower gauge can be more challenging and may require the use of larger wire cutters. A 2/0 gauge wire's amp rating is significant in various applications.

Heres a simplified chart of the ampacity for various common copper wire sizes at 75C, which is the standard temperature rating for many types of wire insulation. These values are provided as a general guide, and it's crucial to consult local electrical codes and specific wire manufacturer data for precise values.

| AWG Size | Diameter (Inches) | Ampacity (Amps at 75C) | Typical Uses |

|---|---|---|---|

| 14 | 0.064 | 15 | Lighting circuits, small appliances |

| 12 | 0.081 | 20 | General-purpose outlets, lighting |

| 10 | 0.102 | 30 | Garbage disposals, air conditioners |

| 8 | 0.129 | 40 | Water heaters, larger appliances |

| 6 | 0.162 | 55 | Electric ranges, main service lines |

| 4 | 0.204 | 70 | Subpanels, large appliances |

| 2 | 0.258 | 95 | Main service lines, large subpanels |

| 1/0 (0) | 0.325 | 150 | Large service entrances, subpanels |

| 2/0 (00) | 0.365 | 175 | Large service entrances, subpanels |

| 3/0 (000) | 0.410 | 200 | Main service lines, heavy-duty applications |

| 4/0 (0000) | 0.460 | 260 | Main service lines, industrial applications |